Taking Care of Your Eyesight

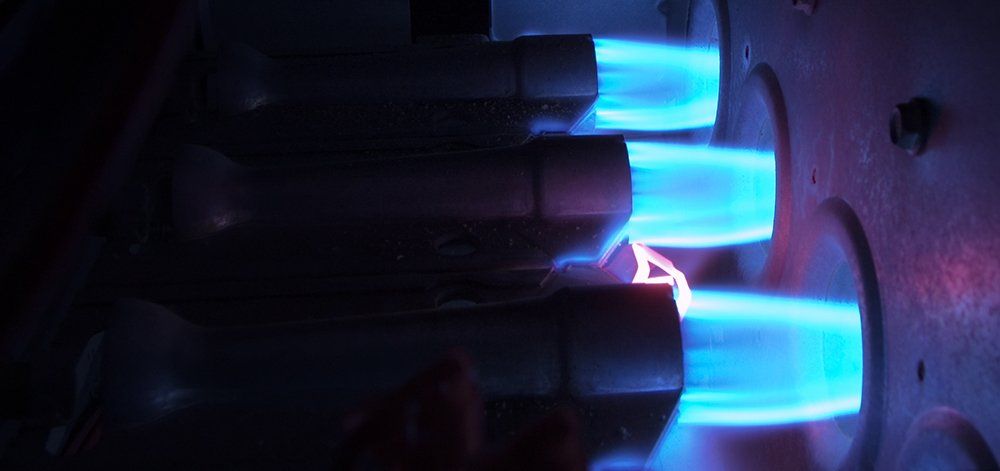

Eye injuries are far too common in the workplace. The National Institute for Occupational Safety and Health (NIOSH) reports about 2,000 U.S. workers sustain job-related eye injuries that require medical treatment each day. The majority of these injuries result from small particles or objects striking or abrading the eye. Examples include metal slivers, wood chips, dust, and cement chips that are ejected by tools, wind-blown, or fall from above a worker. Some of these objects, such as nails, staples, or slivers of wood or metal penetrate the eyeball and result in a permanent loss of vision. Large objects may also strike the eye/face, or a worker may run into an object causing blunt force trauma to the eyeball or eye socket. Chemical burns to one or both eyes from splashes of industrial chemicals or cleaning products are common. Thermal burns to the eye occur as well. Among welders, their assistants, and nearby workers, UV radiation burns (welder’s flash) routinely damage workers’ eyes and surrounding tissue.

In addition to common eye injuries, health care workers, janitorial workers, and other workers may be at risk of acquiring infectious diseases via ocular exposure. Infectious diseases can be transmitted through the mucous membranes of the eye as a result of direct exposure or from touching the eyes with contaminated fingers or other objects.

Fortunately, we can protect against these hazards by using the appropriate protective eyewear for our jobs.

A survey by the Labor Department's Bureau of Labor Statistics (BLS) reveals how and why many on-the-job accidents occur:

- Not wearing eye protection. Nearly three out of every five workers injured were not wearing eye protection at the time of the accident.

- Wearing the wrong kind of eye protection for the job. About 40 of the injured workers were wearing some form of eye protection when the accident occurred. These workers were most likely to be wearing eyeglasses with no side shields, though injuries among employees wearing full-cup or flat-fold side shields occurred, as well.

What Causes Eye Injuries?

- Flying particles. Almost 70% of the accidents studied resulted from flying or falling objects or sparks striking the eye. Injured workers estimated that nearly three-fifths of the objects were smaller than a pin head. Most of the particles were said to be traveling faster than a hand-thrown object when the accident occurred.

- Contact with chemicals caused one-fifth of the injuries.

- Other accidents were caused by objects swinging from a fixed or attached position, like tree limbs, ropes, chains, or tools which were pulled into the eye while the worker was using them.

The BLS reported that more than 50% of workers injured while wearing eye protection thought the eyewear had minimized their injuries. Further, it is estimated that 90% of eye injuries can be prevented through the use of proper protective eyewear. There are several types of eye protection and it’s important you wear the right protection for the task.

Safety Glasses

- Safety glasses with side shields are a good form of eye protection for general use to prevent flying debris and or objects from coming into contact with your eyes.

Safety Goggles

- Goggles offer superior protection from small flying debris and particles as well as chemical splashes.

Face Shields

- When grinding, changing propane or changing batteries, a face shield along with our safety glasses or goggles give additional protection during these types of tasks.

Make wearing protective eyewear a safety habit in your workplace! Take care of your eyesight!

Resources:

- CDC/NIOSH Workplace Safety & Health Topics at www.cdc.gov/niosh/topics/eye/

- Preventing Blindness America at www.preventblindness.org

- Personal stories at www.oakley.com/community/news/bloody-eye/